- Home >

- Products

-

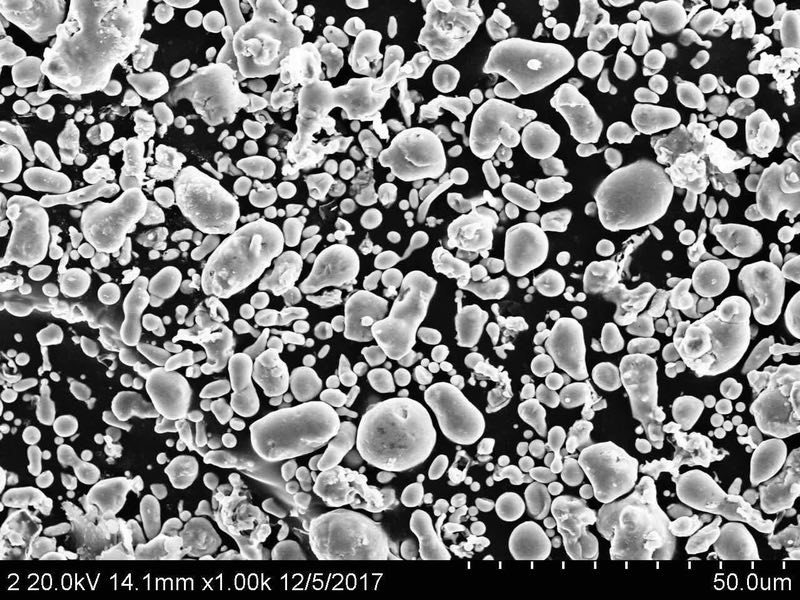

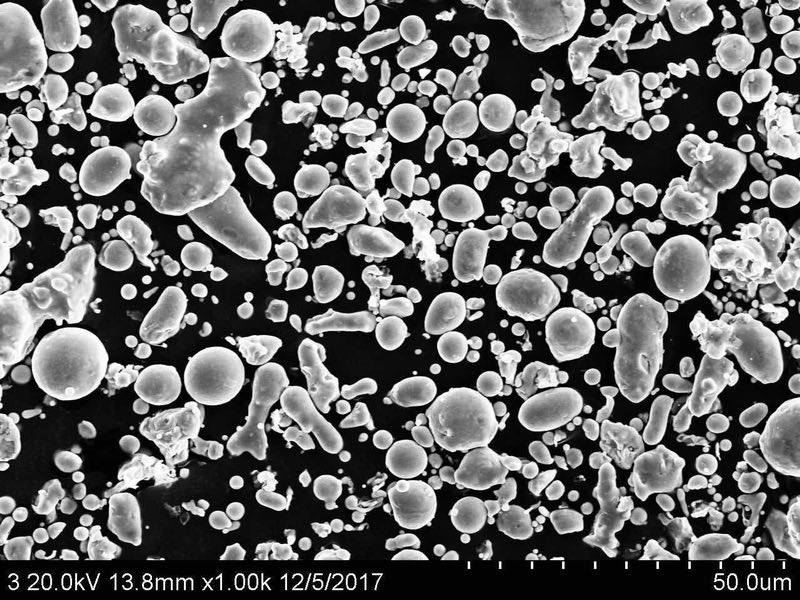

Iron based alloy powder for laser cladding

Laser cladding, also known as laser cladding or laser cladding, is a new surface modification technology. It adds a cladding material on the surface of the substrate and uses a high-energy density laser beam to fuse it together with the thin layer of the substrate surface to form an additive cladding layer on the surface of the substrate that is metallurgically combined.

-

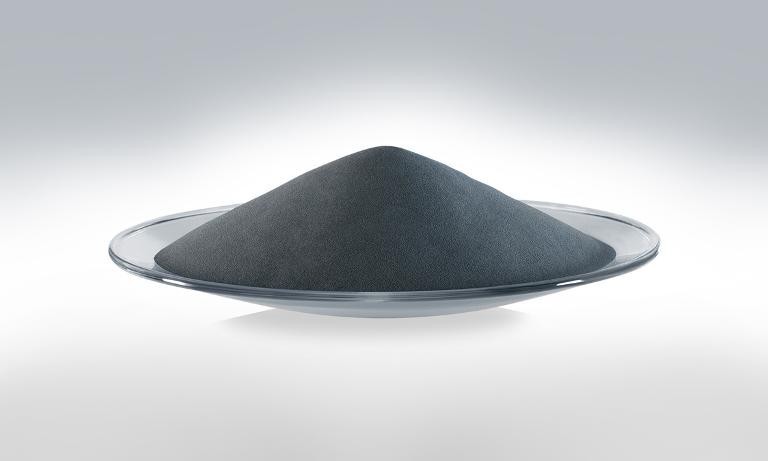

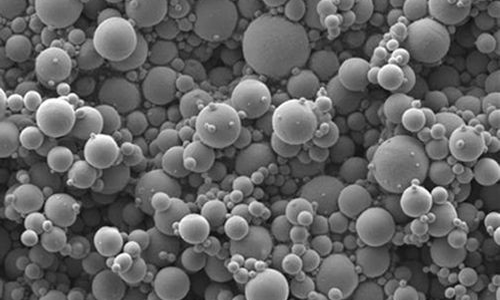

3D printing alloy powders

Established domestic leading 200kg and 500kg high-temperature and high-activity metal powder high-efficiency gas atomization production technology equipment. The fine powder prepared by this technology and equipment has the characteristics of high output rate and low impurity content, which can meet the requirements of 3D printing metal Products, powder metallurgy products for aerospace use, high-purity powder metallurgy targets, metal injection molding, diamond synthesis and tools and other fields use various high-end metal powder needs. Its mass production and application will drive the technological progress of the related metal powder materials and its products industry, which is of great strategic significance. It can greatly improve the quality of domestic related products and relieve the pressure of high production costs caused by imported raw materials. Conducive to its performance/price advantages to participate in international market competition.

-

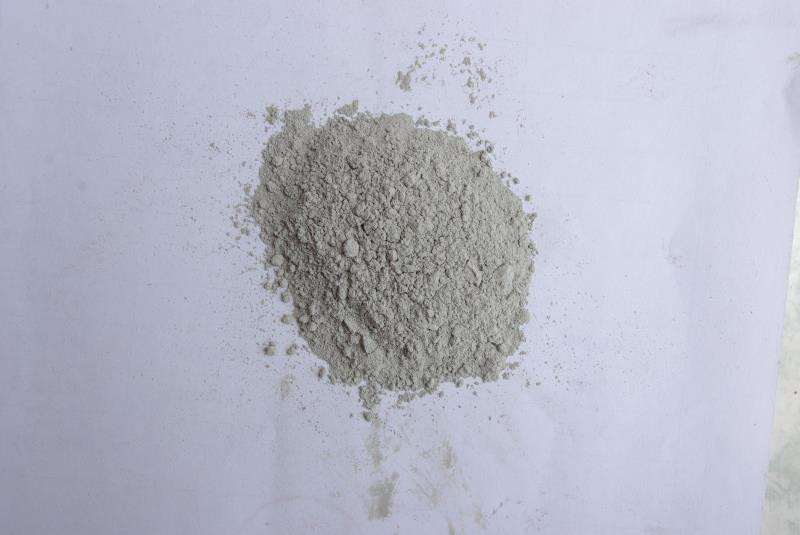

95% Si3N4 powder

This Si3N4 powder has been used regularly by the No.1 customer in this industry. Weclome to ask for samples and test.

-

MIM(metal injection molding) copper powder

1.This copper powder is made of water&gas atomization with much competitive price. 2.Bronze powder is easily oxidized, so we pack it into 10kg vacumm PVC bag. 3. Super low Oyxgen % even lower than gas atomiztion 4. High tap density

-

420J2 MIM powder for metal injection molding

Density of MIM part: 7.5-7.7 g/cm³ Hardness after sintering: 38-40HRC

-

White tungsten alloy feedstock

The MFI of our white tungsten alloy MIM feedstock is ≥1250,The excellent conformality allows metal injection molding factories to produce highly precision products. Besides, the density of the sintered part is higher than 99%.

-

White tungsten alloy MIM powder

Our white tungsten alloy MIM powder is made by water-gas combined atomization process, the powder has spherical shape and good flowability as well. The excellent conformality allows metal injection molding factories to produce highly precision products. Besides, the density of the sintered part is higher than 99%.