-

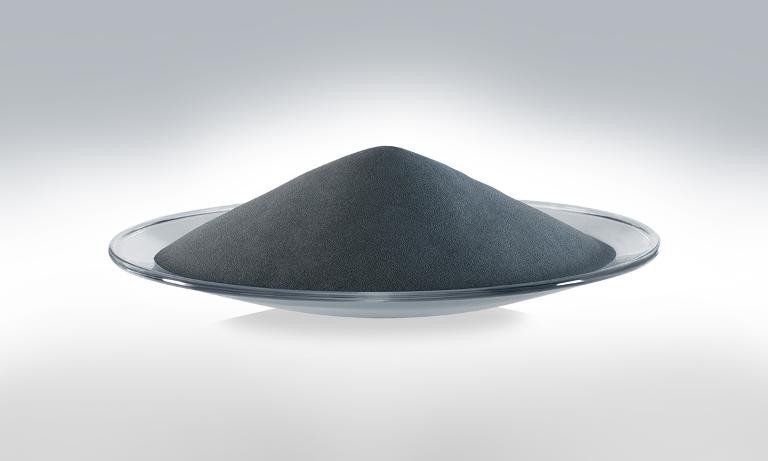

Inconel 713C MIM netshape powder

Powder injection moulding of Inconel 713C alloy was a new type of super alloy MIM powder developed by LIDE MIM POWDER. Sintered temperature: 1300°C for 3 h Density of sintered parts: 7.8g/cm³ Hardness:43.6 HRC Tensile strength:1216.9 MPa.

-

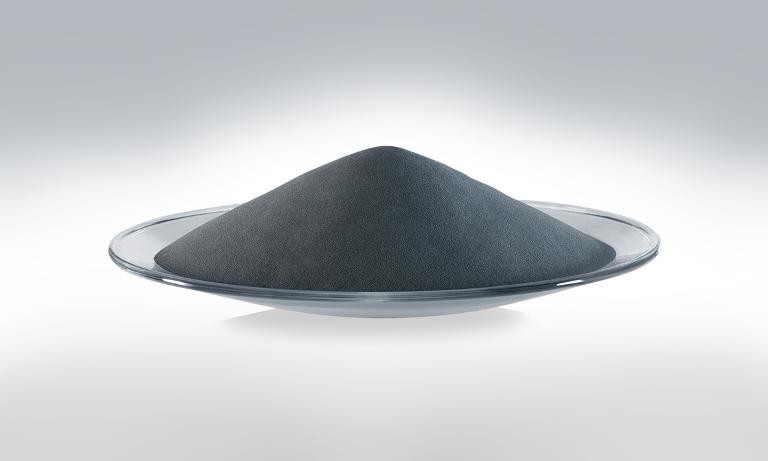

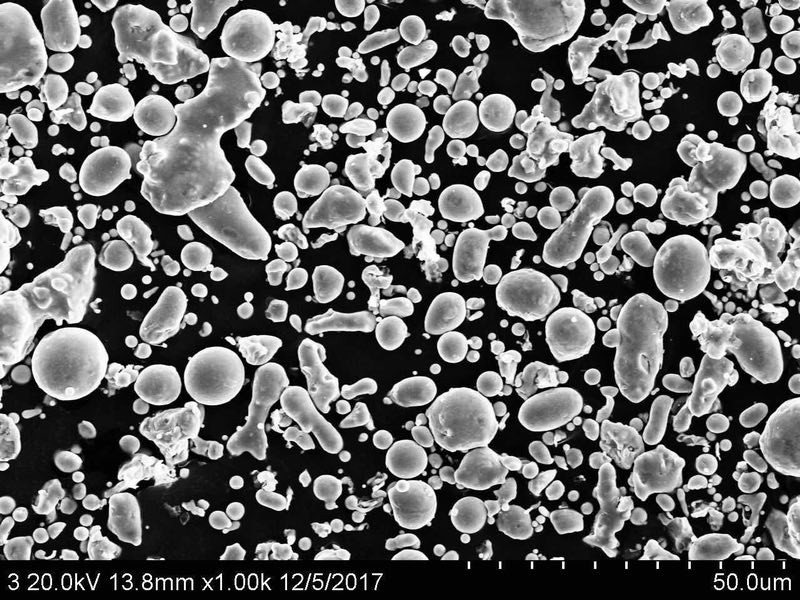

17-4ph MIM powder

Our 17-4ph MIM powder is made by water-gas combined atomization process, the powder has spherical shape and good flowability as well. The excellent conformality allows metal injection molding factories to produce highly precision products. Besides, the density of the sintered part is higher than 99%. It has corrosion-resistant property, excellent mechanical strength. This material is widely used in medical devices, auto parts, tools and machines etc.

-

carbonyl iron powder

Carbonly Iron powder for metal injection molding. 3-7 days delivery time after receiving your PO. 25kg/drum, 1,000KG/PALLET

-

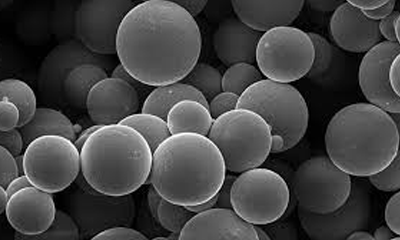

MIM PANACEA

1. Production process: gas atomization PANACEA powder 2. Non-magnetic and nickle free stainless steel powder: PANACEA powder 3. ASTM PANACEA

-

MIM 2507 Forms of Super Duplex 2507

2507 is a super duplex stainless steel designed for applications which demand SUPER strength and exceptional corrosion resistance. MIM(metal injection molding) 2507 has 25% chromium, 4% molybdenum, and 7% nickel which lead to exceptional resistance to chloride stress corrosion cracking. MIM2507 Duplex is highly resistant to uniform corrosion by organic acids such as formic and acetic acid. It is alsohighly resistant to inorganic acids, especially if they contain chlorides. MIM Alloy 2507 is highly resistant to carbide-related intergranular corrosion. Due to the ferritic portion of the duplex structure of the alloy it is very resistant to stress corrosion cracking in warm chloride containing environments. Through additions of chromium, molybdenum and nitrogen localized corrosion such as pitting and crevice attack are improved. Alloy 2507 has excellent localized pitting resistance.

-

F75 MIM powder

Our F75 MIM powder is made by water-gas combined atomization process, the powder has spherical shape and good flowability as well. The excellent conformality allows metal injection molding factories to produce highly precision products. Besides, the density of the sintered part is higher than 99%. This material has corrosion-resistant, wear-resistant, non-magnetic properties, it can be widely used in 3C field and medical industry.

-

MIM(metal injection molding) copper powder

1.This copper powder is made of water&gas atomization with much competitive price. 2.Bronze powder is easily oxidized, so we pack it into 10kg vacumm PVC bag. 3. Super low Oyxgen % even lower than gas atomiztion 4. High tap density