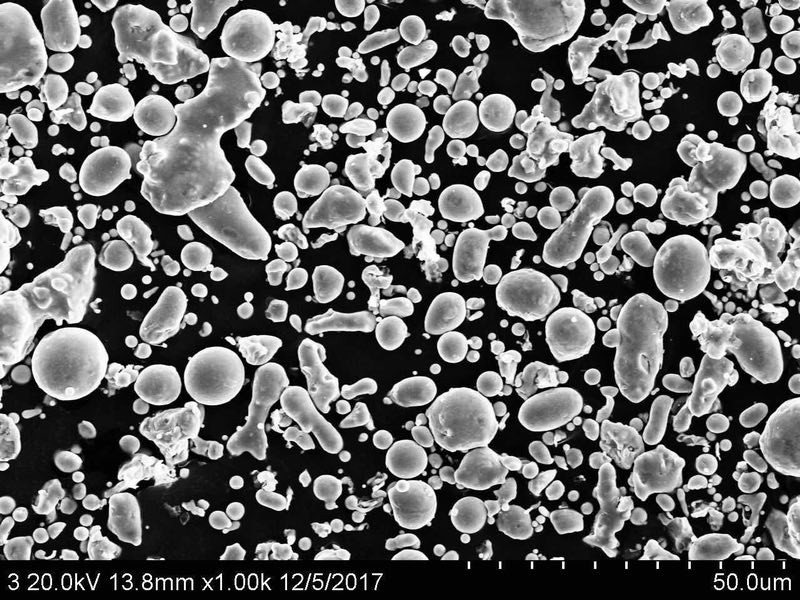

MIM Powder

Inconel 713C MIM netshape powder

Brand :Lide

Product origin :Hebei,China

Powder injection moulding of Inconel 713C alloy was a new type of super alloy MIM powder developed by LIDE MIM POWDER.

Sintered temperature: 1300°C for 3 h

Density of sintered parts: 7.8g/cm³

Hardness:43.6 HRC

Tensile strength:1216.9 MPa.

Inconel 713C super alloy MIM (metal injection molding) powder

Chemical %

| Item | C(%) | O(%) | Si(%) | Mn(%) | P(%) | S(%) | Al(%) | B(%) | Co(%) |

| Standard | 0.05-0.15 | ≤0.5 | ≤0.25 | ≤0.015 | ≤0.015 | 5.5-6.5 | ≤0.015 | ≤1.0 | |

| Results | 0.095 | 0.29 | 0.39 | 0.006 | 0.009 | 0.012 | 5.61 | 0.002 | 0.003 |

| Standard | Cr(%) | Cu(%) | Fe(%) | Mo(%) | Ti(%) | Zr(%) | Nb(%) | Ni(%) |

| Results | 12.0-14.0 | ≤0.5 | ≤2.5 | 3.8-5.2 | 0.5-1.0 | ≤0.15 | 1.8-2.8 | Bal. |

| 12.88 | 0.003 | 1.87 | 4.79 | 0.52 | 0.002 | 1.97 | Bal. |

Particle size distribution:

| Item | D10 | D50 | D90 |

| Standard | 2-4μm | 9-11μm | 21-24μm |

| Results | 2.064 | 9.058 | 24.92 |

Tap density: 4.75g/cm³

Application:

Metal Injection Molding parts applied for high temperature environment

-

Download

- MIM713C-datasheet.pdf

Get the latest price? We'll respond as soon as possible(within 12 hours)